SMART ASSEMBLY OF WOOD POLYMERS FOR MULTIFUNCIONAL ADVANCED MATERIAL

Researcher: Erfan Kimiaei, Doctoral candidate, Aalto University

Supervisor: Professor Monika Österberg, Department of Bioproducts and Biosystems, School of Chemical Engineering, Aalto University

Background of the project: Answering the call for sustainability, there is growing demand to develop bio-based materials from renewable sources. Lignin, as the second-most abundant biopolymer, has great potential to valorize industrial side streams to replace many fossil-based materials. However, its inherent heterogeneity and complex structure have hindered commercialization of lignin, resulting in the majority of it being burned for energy production.

We valorize poorly soluble lignin into a colloidal lignin nanoparticle (CLP) suspension by tailoring their surface properties, showing great potential for lignin utilization. CLPs are an integral component in this research, enabling us to develop multiphase systems thanks to their tunable surface and amphiphilic properties.

Strong, flexible and multifunctional biocomposite is made by a smart combination of colloidal lignin nanoparticles (CLPs) with wood polymers and extractives.

Aim of the project: The primary aim of this project is to provoke well-defined functionalized, bio-based materials for large-volume commercial applications, such as nanocomposites and foams, by unravelling the interfacial properties of wood-based resources and renewable polymers as well as their colloidal assembly, addressing the important scientific challenges in colloid and interface science. To achieve this ambitious goal, we use our expertise in colloid and surface chemistry. We rationally design emulsion-based systems by controlling the interfacial interactions

between wood polymer building blocks. Generated colloidal systems can be used as a platform to fabricate biomaterials for a varied range of applications with additional bioactivity and competitive mechanical performance compared to synthetic materials. This strategy allows us to avoid excessive chemicals and treatments that facilitate the sustainable use of wood components originated from Finnish natural resources, thus bringing positive societal impacts for the development of high value-added materials.

FINPOWDER: DESIGN OF SPRAY DRIED FINNISH WILD BERRY POWDER PARTICLES USING WOOD-BASED POLYSACCHARIDES TO PROTECT ITS BIOACTIVE COMPOUNDS

Researcher: Abedalghani Halahlah, Doctoral student, Department of Food and Nutrition University of Helsinki.

Supervisors: Associate Professor Kirsi S. Mikkonen and Dr. Minh Thao Ho, Department of Food and Nutrition, University of Helsinki.

Description of the project: The FinPowder project aims to develop a new strategy to develop sustainable and healthy food choices for global consumers while valorizing Finnish wood-based polysaccharides and wild berries. FinPowder will design powder particles to protect healthy and functional phenolic compounds and vitamins found in wild berries during spray drying. The wood polysaccharides to be trialed include both established hydrocolloids and emerging candidates. We aim to optimize spray drying conditions in the hope to achieve stable powder particles. FinPowder will also examine the physiochemical properties, stability, and digestibility of these novel wild berry powders to provide information about their storage, handling and application possibilities. In parallel, this will also allow us to determine their nutritional value, bioavailability and bioaccessibility.

We plan to exploit wood-based hemicelluloses sourced from waste by-products of the Finnish wood processing industry, to facilitate the production of natural and functional products. The aim is to dramatically improve on the existing methods (e.g., burning for energy or hydrolysis into monosaccharides) in terms of sustainability. The spray drying process will be developed in a manner that allows it to be rapidly scaled up and transferred to food processing companies for commercial and high throughput production of wild berry powders. The project has the potential to contribute to wild berry businesses in Finland as it opens the possibility to increase berry product exports internationally. It will also expand on the way consumers will be able to use berries in their every-day meals, supporting a healthy, nutritious diet and prevention of chronic diseases. More broadly, FinPowder will support the sustainable, circular development objective of the Finnish economy by using its natural resources more effectively.

The expected outcomes of the project are a doctoral thesis completed by Abedalghani, including at least three high-impact scientific papers. The highlight being a detailed strategy for the production of high-value, low-cost and easy-to-consume food products from two Finnish natural resources (wild berries and wood biomass) to meet the increasing demands for sustainable and healthy food choices across the globe

NEW GENERATION OF LOW ENVIRONMENTAL IMPACT ENERGY STORAGE SYSTEMS FROM FOREST PRODUCTS

Researcher: Dr. Josphat Phiri, D.Sc. (Tech), Postdoctoral researcher, Aalto University

Supervisor: Professor Thad Maloney, Ph.D., Aalto University, School of Chemical Engineering, Department of Bioproducts and Biosystems.

Description of the project: The main objective of this project is to develop energy storage devices that are based largely on low environmental impact, renewable and sustainable materials from lignocellulosic materials such as those from the forest industry. The demand for energy storage systems has increased rapidly in recent years due to new technological advancements in various portable electronic devices and the dire need for renewable energy sources that could have a greater influence on the global climate change. The production of renewable energy depends on the availability of energy storage systems because energy must be efficiently stored when available especially in the case of solar energy. Therefore, it is vital to have efficient energy storage systems that can not only store but also release it when needed.

needed.

The application of energy storage devices is vast. Some examples of these applications include mobile phones, hybrid electric vehicles, trains, trolleybuses, uninterruptible power supplies, computers, energy harvesting systems, electric vehicles, solar panels or wind turbines, body sensors, hearing aids etc.

The most common types of energy storage systems are batteries, solar cells, and supercapacitors. At the heart of all energy storage devices are electrodes. Electrodes play a significant role in the performance of all energy storage devices. As such, this project emphasizes the design and fabrication of electrodes which could in theory be applied in various energy storage systems. Developing electrodes with a well-defined pore structure and high surface area is vital for the performance efficiency. The surface area and pore structure can be influenced by the type of biomass used and the fabrication conditions. Therefore, various methods for activation of biomass will be investigated as well as various biomass sources such as waste products from pulp and paper industry.

Furthermore, commercially, electrodes are fabricated using toxic binders. In this project, we also investigate the possibility of using modified cellulosic materials as potential substitutes to the fossil-based counterparts and how efficient they perform. In addition, we also explore the possibility of fabrication an all carbon-carbon composite system from renewable and sustainable sources, which is expected to also enhance the efficiency and performance of the devices.

This project is expected to promote the use of the Finnish forest industry as a source for renewable and sustainable materials for fabrication of high-end devices for energy storage application which is vital in this bio-economy society. In addition, the transformation of waste into high-end application can show that it is possible to reduce the environmental pollution strain caused by certain waste products that has potential to be transformed into high value products.

FROM FOREST INDUSTRY WASTE STREAMS TO NEW URETHANSE AND POLYURETHANES:VALUE FROM LIGNIN DEGRADATION

Researcher: Veronika Badazhkova, Doctoral student, Åbo Akademi University

Supervisors: Professor Reko Leino (Principal investigator), Dr. Risto Savela and Dr. Patrik Eklund

Site of Research: Johan Gadolin Process Chemistry Centre, Laboratory of Molecular Science and Technology, Åbo Akademi University

Description of the project: Polyurethanes belong to the most important polymeric materials and, due to their highly versatile properties, are used in several different applications, including tubings, footwear, industrial machinery, coatings and paints, elastic fibers, rigid insulations, soft flexible foams and medical devices. Traditionally, polyurethanes are produced from isocyanate monomers, which are often highly toxic and moisture sensitive. Alternatively, properly sized cyclic carbamates could be polymerized by cationic ring opening polymerization. A possible biomass based feedstock for polyurethanes could be lignin. It is one of the most abundant organic polymers available on earth, constituting ~30% of non-fossil based carbon and approximately 20-35% of dry mass of wood. Comprised of aromatic monomers, lignin can be considered as one of the most abundant natural resources for future aromatic platform chemicals. Suitable cyclic carbamates could be prepared catalytically from lignin by alcohol amination reaction followed by carbon dioxide fixation, thus allowing the minimization of chemical waste formed in process. The objective of this project is to discover suitable methodologies for the utilization of waste streams from Finnish forest industry to facilitate the production of biomass based polyurethanes.

DEVELOPMENT AND MODIFICATION OF SCANDIUM PRODUTION PROCESS

Researcher: M.Sc. Rita Kallio

Supervisors: Professors Timo Fabritius (metallurgy), Saija Luukkanen (Mineral processing) and Ulla Lassi (Hydrometallurgy)

Description of the project: Scandium provides technological advantages, particularly in solid oxide fuel cells and aluminum alloys, in respect of transportation applications due to its capacity to increase strength and weldability. The focus of this project is to develop a material and cost-efficient process to extract scandium from the recently discovered Kiviniemi mafic intrusion, which is a primary scandium occurrence with estimated 13.4 Mt @ 163 ppm Sc. Based on the geochemical characteristics of scandium, its enrichment to ore grades by geological processes is scarce. Consequently, the estimated global scandium production is currently only 15 t/a. Given the limited volume of the current global scandium production, the Kiviniemi deposit provides a potential new source for the expectedly increasing demand of this unique rare earth metal, classified as a critical raw material for the European Union. There are no other Kiviniemi-type scandium deposits known in Europe. In the Kiviniemi deposit, scandium occurs in pyroxene and amphibole, which respond well to magnetic preconcentration (Figure 1). In addition to the conventional preconcentration methods, the proposed processing scheme investigated in this research project includes high-temperature upgrading of the concentrate to produce Sc-containing amorphous phase along with crude iron. The Sc-containing amorphous phase is further treated with hydrometallurgical processes to produce the desired Sc2O3-product. The purpose of this research is to investigate the main features and boundary conditions related to each proposed step, the results of which will be published in relevant journals. This project promotes the beneficiation of the Kiviniemi scandium deposit through interdisciplinary research, extending from mineral processing to the pyrometallurgical treatment and hydrometallurgical aspects of scandium extraction.

Figure 1. Stereomicroscope images of dry magnetic separated fractions from a Kiviniemi sample. The dark particles (black and green) represent scandium-containing pyroxene and amphibole, together with ilmenite, iron oxides and sulfides. The red grains are garnet (almandine) and the colorless or slightly yellow/orange grains are mainly plagioclase and potassium feldspar. A-D): 250-500 µm size fraction separated with A) hand magnet, B) Frantz 0.4 A, C) Frantz 0.8 A and D) Nmags; E-H): 125-250 µm size fraction; I-L): 63-125 µm size fraction; and M-P): 32-63 µm size fraction, separated in respective order.

COMPARING THE IMPACT OF CONTINOUOUS COVER FOREST MANAGEMENT AND ROTATIONS FOREST MANAGEMENT ON LONG-TERM SOIL CARBON STORAGE

Researcher: Eva-Maria Roth, Doctoral student, University of Helsinki

Supervisors: Assistant Professor Kristiina Karhu, Department of Forest Sciences, University of Helsinki

Professor Eeva-Stiina Tuittila, Faculty of Science and Forestry, School of Forest Sciences, University of Eastern Finland

Professor Heljä-Sisko Helmisaari, Department of Forest Sciences, University of Helsinki

Description of the project: The project promotes the sustainable use of forest soils. Forest soil is a very important natural resource that holds many functions. It provides a habitat for soil biota, enables tree growth and stores carbon. The ability of forests to fix and store atmospheric carbon has brought them into focus as a means to mitigate climate change. The carbon is stored in biomass and, to a greater extent, as organic matter in the soil. Soil organic matter greatly affects the productivity of the soil and thereby tree growth.

Continuous cover forestry is a management system that was discouraged in Finland until 2014. In contrast to the more common rotation forest management, harvesting in continuous cover forestry does not involve clear-cuts. A continuous forest cover remains permanently. Forests managed with continuous cover forestry were found to have a higher ecological resilience, enabling them to adapt to climate change and react to threats, such as bark beetle calamities or storms. My dissertation aims to compare the effects of continuous cover forestry and rotation forest management on long-term soil carbon storage and on the main drivers in the stabilization of soil carbon. I am conducting field studies on experimental plots in central Finland. Because of the reduced soil disturbance during harvests, continuous cover forestry prevents losses of carbon from the soil, which could result in higher long-term soil carbon storage.

- Researcher Eva-Maria Roth

DETAILED SOLUTION CHEMISTRY OF FLOTATION CIRCUITS IN NORDIC CONDITIONS

Researcher: David Sibarani (M.Sc.), Doctoral student, Aalto University

Supervisor: Daniel Lindberg (D.Sc.), Associate professor, Principal Investigator and supervisor.

Aalto University, School of Chemical Engineering, Department of Chemical and Metallurgical Engineering.

Description of the project: The goal of this project is to study the aqueous chemistry in mineral processing of sulfidic ores, where the water circulation of the flotation circuits are closed and the same water circulates between the mineral processing plant and the tailing pond. Closed water cycles will change the composition of the water used in the mineral processing, which will be problematic, e.g., in flotation processes. The properties of the aqueous phase in the flotation processes has not been studied in detail to any large extent due to lack of proper tools for these studies. In the present project, the goal is to systematically and critically develop thermodynamic databases for aqueous solutions, with the following areas of application:

- The detailed solution chemistry of the aqueous phase in mineral processing of sulfidic ores, with a focus on Nordic conditions.

- The detailed solution chemistry of acidic leachate waters from mines, as well as the recovery of metals from these solutions.

The project will promote the Finnish mining and metallurgical industry, as well as the development of circular economy through

- increased utilization and recycling of the process water from flotation processes

- more efficient utilization of mineral resources

- increased metal recovery from depleted mines and waste heaps.

The expected outcome is a doctoral thesis, including several scientific papers, as well as a detailed thermodynamic database that can be utilized by the Finnish industry to further optimize metals recovery from complicated processes and streams.

- David Sibarani

- Supervisor Daniel Lindberg

BOOSTING THE USE OF FAST-GROWING ASPEN: GREEN SOURCE OF HIGH-ADDED VALUE CHMICALS AND ENERGY (BoostA)

Researcher: Pasi Korkalo, Research Scientist. M.Sc. (Chemistry), Natural Resources Institute Finland

Supervisor: Tuula Jyske, Senior Scientist, D.Sc., docent (Agr & For), Natural Resources Institute Finland

Researcher Pasi Korkalo

Background of the project

Novel bioeconomy approaches call for more and faster production of lignocellulosic biomass and its better-tailored holistic use for higher added value. Hybrid aspen (Populus tremula L. x P. tremuloides Michx.) is one of the fastest growing tree species in Finland. The high yield capacity and chemical properties of aspen indicate its promising potential for biochemicals and green energy.

Aims of the project

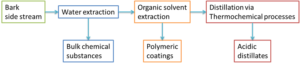

We study the chemical properties of hybrid aspen clones for production of added-value chemicals. We concentrate on aspen bark as an under-utilized raw material. By using extraction and thermochemical distillation, chemical substances are separated for case studies (Figure).

Figure: Comprehensive utilization of hybrid aspen wood and bark.

How the project will promote the sustainable use of Finnish natural resources

To remain competitive in future bio-economy, the Finnish forest sector must constantly come up with novel products. Hybrid aspen has potential to become a more important raw material in Finland, especially as the climate change forces a broadening of the selection of commercially utilized tree species. Our project promotes the comprehensive utilization of aspen biomass. Aspen bark may provide an alternative source for fossil-based chemicals.

Expected results and deliverables

The project provides forest industries and future bio-refineries with a knowledge base on hybrid aspen biomass, especially the under-utilized bark, and its potential for added-value applications or template chemicals including:

1) catalytic conversion of wood-derived substances into valuable bulk chemicals

2) application of suberin acids in coatings

3) use of acidic distillates for plant protection.

NEW METHODS FOR PURE RARE EARTHS/PuREE

Researcher: M.Sc. Santeri Kurkinen, Department of Separation Science, LUT University

Supervisors: Prof. Tuomo Sainio and Dr. Sami Virolainen, LUT University

Description of the project: Rare earth elements (REEs) are a set of 17 elements with extraordinary properties. Their numerous applications include electronics, LEDs, high strength magnets, automotive catalytic converters, and high temperature superconductors. REEs are not particularly rare in Earth’s crust, but they are difficult to extract and purify cost-effectively.

Besides ores, REEs are found in various by-products of minerals processing. Phosphogypsum waste (PG), which is formed in phosphate fertilizer production, may contain 0.2 wt-% of REEs. PG is available in huge quantities. In Finland alone, more than 1.5 million tons of PG is produced and piled annually.

REEs can be leached from PG with, e.g., sulfuric acid. Interestingly, leaching can be done under very mild conditions if functionalized polymeric particles, called ion exchange resins, are added to the leaching reactor. The polymer particles quickly bind the liberated REE ions from the solution, thus increasing the leaching yield.

The PuREE project aims at further developing the “resin-in-leach” process. Significant improvements in leaching efficiency and selectivity are achieved by optimizing the chemistry of the functionalized polymer. Once the REEs are bound to the polymer, they must be recovered to reuse the polymer. The sustainability of this step is improved by using biodegradable chemicals for REE recovery. Further purification of the REEs is done in a separation column using another type of polymeric separation material.

The PuREE project produces new data and process options for sustainable production of REEs from a secondary source in Finland.

Dr. Virolainen and M.Sc. Kurkinen being busy in recovering of REEs from phosphogypsum